The workflow of an Aluminum Foundry explained in simple terms

Wiki Article

Comprehensive Guide to the Uses and Manufacturing Techniques in Aluminum Foundry Operations

The comprehensive overview to light weight aluminum shop procedures offers vital insights into the diverse applications of aluminum throughout different industries. It methodically takes a look at vital production methods, thawing processes, and molding methods that contribute to precision and quality. In addition, the guide highlights the value of ending up processes that boost both mechanical residential properties and appearance. Recognizing these elements is essential for any individual involved in aluminum production, raising concerns about finest methods and developments in the field.Review of Light Weight Aluminum Casting Applications

Furthermore, the construction market advantages from light weight aluminum spreadings in architectural components and architectural parts, providing sturdiness and resistance to rust. Durable goods, such as cookware and home appliances, also utilize aluminum castings for their warmth conductivity and visual allure. The electronics market relies upon light weight aluminum for housings and warm sinks, making certain efficient thermal management. Overall, aluminum casting's versatility enables it to meet diverse market demands properly, solidifying its relevance in modern manufacturing techniques.

Key Production Techniques in Light Weight Aluminum Factory

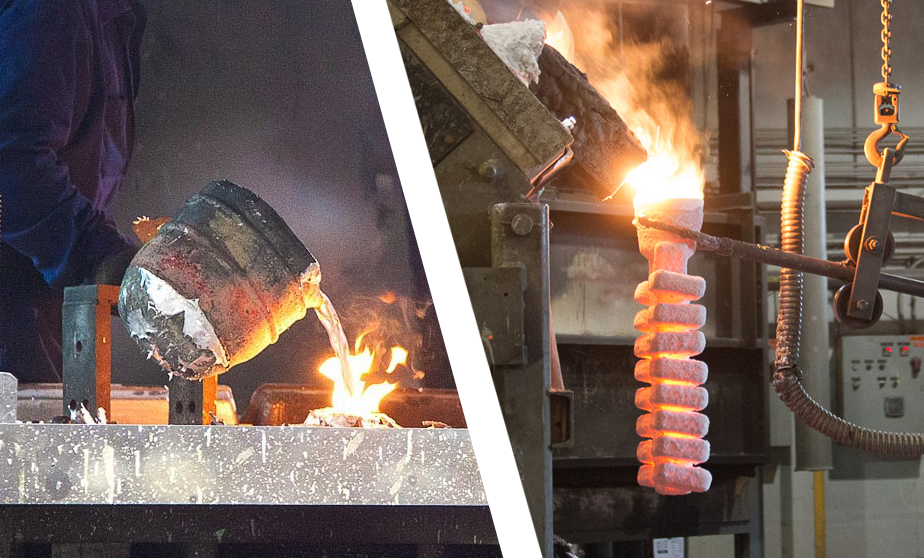

In the domain of aluminum factory operations, different manufacturing techniques play a crucial role fit the end products that serve varied industries. Aluminum Casting. Trick strategies include sand casting, die spreading, and investment casting, each offering distinct advantages based on the application demandsSand casting makes use of a mix of sand and binder to develop mold and mildews, enabling complex geometries at reduced costs. Pass away casting, on the other hand, uses high-pressure shot of molten aluminum right into steel molds, ensuring precision and a smooth surface area coating, ideal for high-volume manufacturing. Investment spreading supplies exceptional dimensional precision and surface area quality, making it ideal for complex layouts.

In addition, methods such as permanent mold and mildew casting and gravity pass away casting additionally enhance the convenience of light weight aluminum shop operations (aluminum foundry). Each method is chosen based on aspects like production volume, component complexity, and product properties, making sure favorable results across numerous applications

Melting Processes and Temperature Level Control

Efficient melting procedures and accurate temperature level control are fundamental for attaining perfect light weight aluminum shop procedures. The melting of aluminum normally includes various techniques, consisting of crucible melting, induction melting, and rotating melting, each with its own advantages and applications. Crucible melting is typically utilized for tiny sets, while induction melting provides efficient heating and uniform temperature distribution.

Molding Strategies for Precision Castings

Grasping molding strategies is vital for producing precision spreadings in light weight aluminum foundry procedures. Numerous methods, such as sand, financial investment, and pass away casting, play a crucial duty in attaining wanted resistances and surface coatings. Sand spreading, for circumstances, makes use of a combination of sand and binder to develop molds, permitting huge elements and elaborate layouts. Financial investment spreading, on the various other hand, utilizes wax patterns that are coated in ceramic material, leading to extremely detailed and specific shapes. Pass away casting utilizes high-pressure shot of liquified light weight aluminum into steel mold and mildews, making sure consistent measurements and quick production rates.Each method has its advantages and is chosen based on elements such as complexity, volume, and mechanical residential properties required. Reliable mold and mildew style, including venting and gating systems, better improves the quality and precision of the finished item. Recognizing these molding methods makes it possible for foundries to satisfy details sector requirements and enhance general functional pop over here efficiency.

Finishing Procedures to Enhance Aluminum Components

Ending up processes play a crucial function in improving the performance and visual appeals of aluminum elements. These procedures, which comply with spreading, purpose to improve surface area high quality, rust resistance, and mechanical residential properties. Typical strategies include machining, which improves measurements and surface area coating, and sprucing up, which improves visual charm by developing a smooth, reflective surface area.Plating is an additional significant procedure, providing a resilient oxide layer that secures against wear and corrosion while enabling color modification. In addition, powder covering supplies a wide variety of finishes and shades, making certain both defense and visual enhancement.

In many cases, parts may undergo shot blowing up to improve and remove pollutants bond for subsequent coatings (aluminum foundry). Generally, these finishing procedures are crucial for maximizing the capability and lifespan of light weight aluminum parts, making them appropriate for varied applications throughout different markets

Regularly Asked Inquiries

What Precaution Are Necessary in Aluminum Foundry Workflow?

In aluminum factory procedures, important precaution include personal safety tools, proper ventilation, fire prevention procedures, normal devices maintenance, training for employees on dangers, and preserving clear emergency situation procedures to ensure a secure workplace.Just How Do Environmental Rules Effect Light Weight Aluminum Foundries?

Environmental guidelines significantly impact aluminum shops by implementing requirements for exhausts, waste administration, and resource consumption. Compliance frequently demands financial investments in cleaner modern technologies and procedures, ultimately influencing operational costs and manufacturing performance within the industry.What Career Opportunities Exist in Light Weight Aluminum Foundry Procedures?

Various job opportunities in aluminum shop procedures include duties such as shop service technician, mold designer, quality assurance assessor, process engineer, and production manager, each adding to effective manufacturing and ingenious procedures within the industry.Exactly How Is High Quality Control Achieved in Light Weight Aluminum Casting?

Quality control in aluminum spreading is attained with rigorous examinations, standardized testing procedures, and the usage of sophisticated modern technologies. Regular tracking of temperature level, structure, and dimensional accuracy warranties items meet specified standards and consumer demands.What Are the Typical Defects in Light Weight Aluminum Castings and Their Causes?

Common defects in light weight aluminum castings include shrinking, porosity, and surface roughness. Causes often come from incorrect mold style, inadequate pouring strategies, and contamination, affecting the general stability and performance of the end product.The considerable overview to light weight aluminum shop operations presents important insights into the varied applications of light weight aluminum throughout different markets. Light weight aluminum casting plays a crucial duty in numerous sectors due to its convenience and favorable buildings. Pass away spreading, on the other hand, employs high-pressure shot of liquified aluminum browse around this web-site into steel mold and mildews, making certain accuracy and a smooth surface area finish, ideal for high-volume manufacturing. Furthermore, methods such as permanent mold and mildew spreading and check over here gravity die casting further boost the convenience of light weight aluminum foundry procedures. Grasping molding methods is vital for producing accuracy spreadings in aluminum shop operations.

Report this wiki page